TEMPERATURE CONTROL SYSTEM

TEMPERATURE :

We need to know how temperature is actually created and how to control the temperature. For the maintenance of nature, just as temperature is generated from the sun, we have to generate temperature ourselves for the convenience of many works. Temperature is a type of energy that makes our body feel cold or hot. When energy is transferred from one of the two objects to the second, the first is hotter than the second. One acquires more heat than the other. In other words, temperature is a force related to the motion of the molecules of matter.

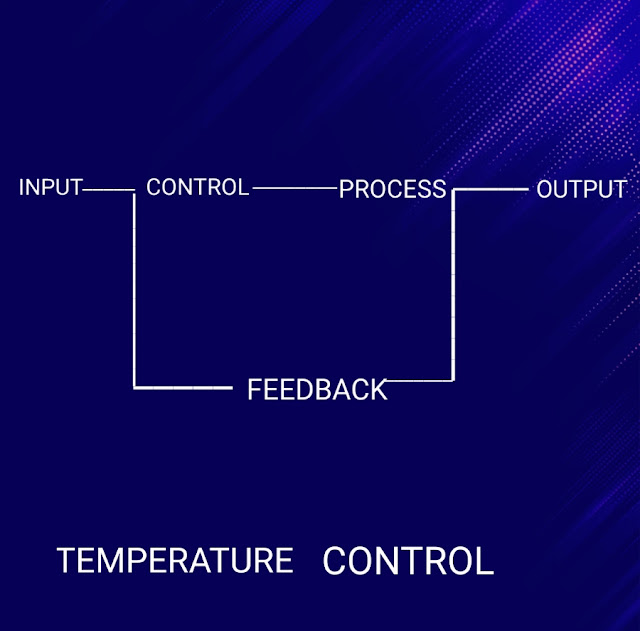

How To Control The Temperature :

Temperature control is directed at maintaining electronic component temperatures within pre-scribed limits. This is accomplished by the proper selection and application of materials which are used to conduct heat from or to the components.

The primary modes of heat transfer are conduction, convection, and radiation. The dominant considerations for heat transfer material selection include thermal conductivity, chemical inertness, resistance to corrosion, and sometimes wear resistance, sublimation, thermal expansion, and the ability to resist ionizing and ultraviolet radiation.

Conduction heat transfer involves the flow of thermal energy through a material from a heat source (component) to a heat sink. The design goal is to reduce the resistance to heat flow between the heat source and the heat sink. The effectiveness of heat transfer within a material is measured by its thermal conductivity. Metals such as silver, copper, and aluminum are good heat conductors; however, aluminum is most often used because it tends not to tarnish, is easy to form, and costs less. Copper or copper alloys are used when large amounts of heat are to be transferred and any small improvement in thermal conductivity is meaningful in the design.

When the design requires electrical insulation and good thermal conduction across a joint between two materials, thin layers of mica, silicon-impregnated cloth, and ceramic materials are often used. The thermal conductivity of these joints may be enhanced by applying a thermal grease to the joining parts to prevent the entrapment of air or other gas (a thermal insulator) between the mating surfaces.

Convection heat transfer involves the movement of heat between one material (usually metal) to a surrounding material such as a gas (air) or a liquid (water, Freon, etc.). A convection design seeks to conduct heat from a heat source into a physical configuration, such as fins, which presents a relatively large area of contact between the metal object and the gas or liquid with which the heat is to be exchanged. Good thermal conductivity is very important so is strength and resistance to corrosion. Convection heat sinks are often made from high-strength aluminum alloys to meet these requirements. For resistance to corrosion, which may result in the formation of a thermally insulating film between the heat transfer media, the aluminum heat sink is sulfuric acid anodized black in color to also enhance heat transfer by radiation.

Convection heat transfer may be improved by mechanically moving cooling gas over the heat sink fins. This is called forced convection, and by using forced convection, the cooling effects of the heat sink may be greatly improved. Of course, forced convection is only effective when an atmosphere is present, and the ability of the forced convection design to handle a given heat load is strongly affected by the density and pressure of the cooling media.

Radiation heat transfer is the primary mode of heat transfer when considering space applications. Radiation at sea level can contribute 10% or more of the total heat transfer process depending on the temperature gradient and distance between the radiating and receiving objects.

Radiation heat transfer applications feature use of thermal conductive materials to transfer heat to radiating surfaces. The effectiveness of the radiation surface emissivity is dependent on the finish applied to those surfaces. For materials which are to reduce the reception or reduce the ability to emit heat, the surfaces are smooth and shiny. Such surfaces are often electroplated with a material such as gold, chromium, or nickel which is chemically inert and may be buffed to a very high gloss. For materials for which the design requires effective heat absorption or emission, the material surface is not smooth (increasing surface area) and is usually black or another dark color. This is achieved on aluminum surfaces by application of a black sulfuric anodize finish such as used on the internal elements of solar collector devices.

Paint on a surface adds a layer of insulation and thus is an impediment to radiation heat transfer. Due to the surface roughness of painted surfaces, the color of the paint usually makes only small differences in surface radiation emissivity; however, a light-colored (white) paint will be somewhat less efficient at radiation heat transfer than a dark (black) paint under extreme thermal loads. Plastic and ceramic materials are not effective radiation heat transfer materials and may be employed as surface insulators to reduce the effectiveness of radiation heat transfer.

0 comments:

Post a Comment

Please do not enter any spam link in the comment box.